Mechatronics System Design

Experienced

Hello, I'm

Automation Engineer

Discover More

1+ years

Automation

M.Sc. Robotics

B.Tech. Mechatronics

I'm an Automation Engineer with a B.Tech in Mechatronics and M.Sc in Robotics, specializing in industrial control systems. My expertise includes PLC programming (Rockwell), SCADA/HMI development (FactoryTalk), and industrial network integration (Ethernet/IP, Profibus). With hands-on experience in panel testing, sensor integration, and troubleshooting automation systems, I'm passionate about developing efficient and reliable industrial solutions. I thrive on implementing smart control systems that optimize performance and drive innovation in industrial automation.

Experienced

Experienced

Experienced

Experienced

Experienced

Experienced

Experienced

Experienced

Experienced

Experienced

Experienced

Experienced

Browse My Recent

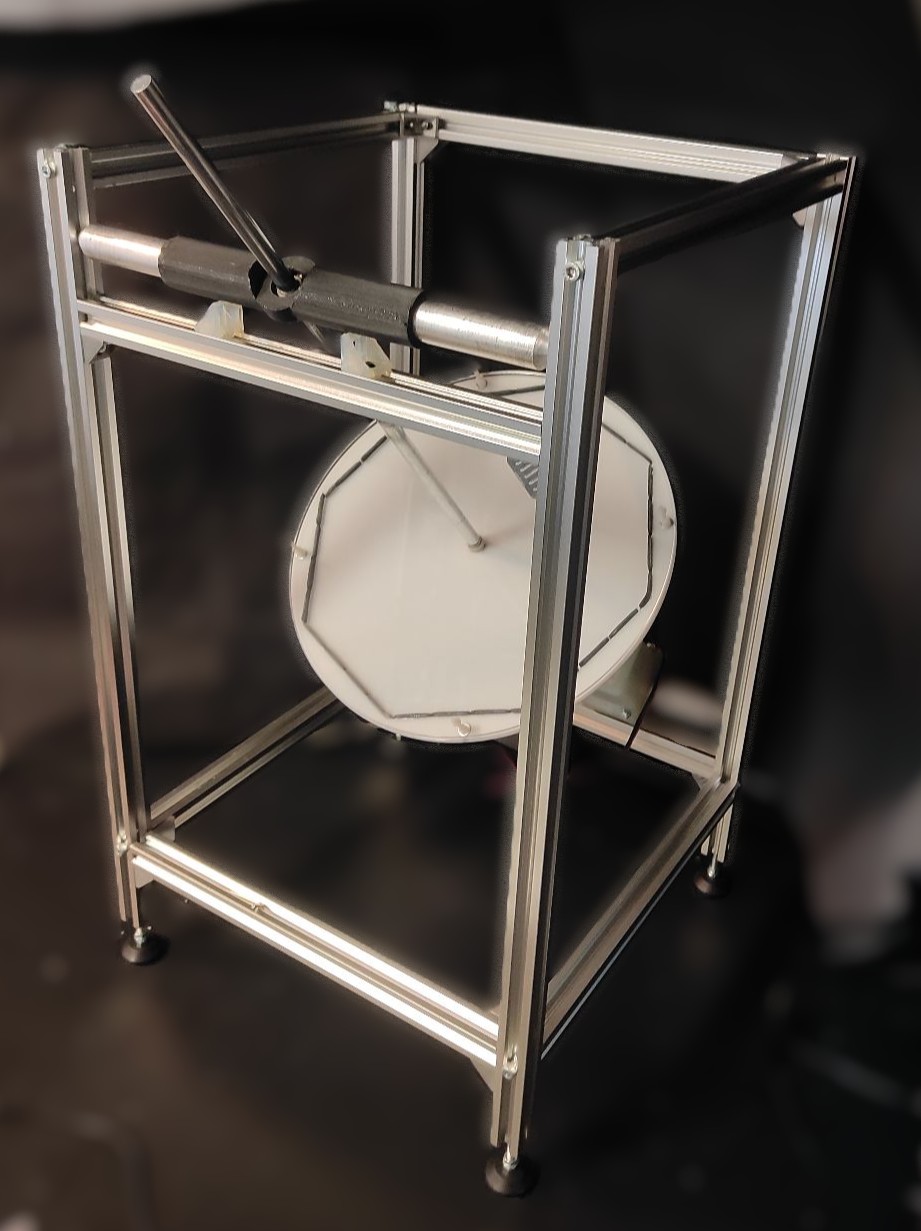

Designed and tested a specialized agitation system to compare the efficiency of two-dimensional and three-dimensional modular self-assembly in robotics. The findings advance understanding of self-assembly dynamics in modular robotics, providing valuable insights for applications in adaptive manufacturing and space exploration.

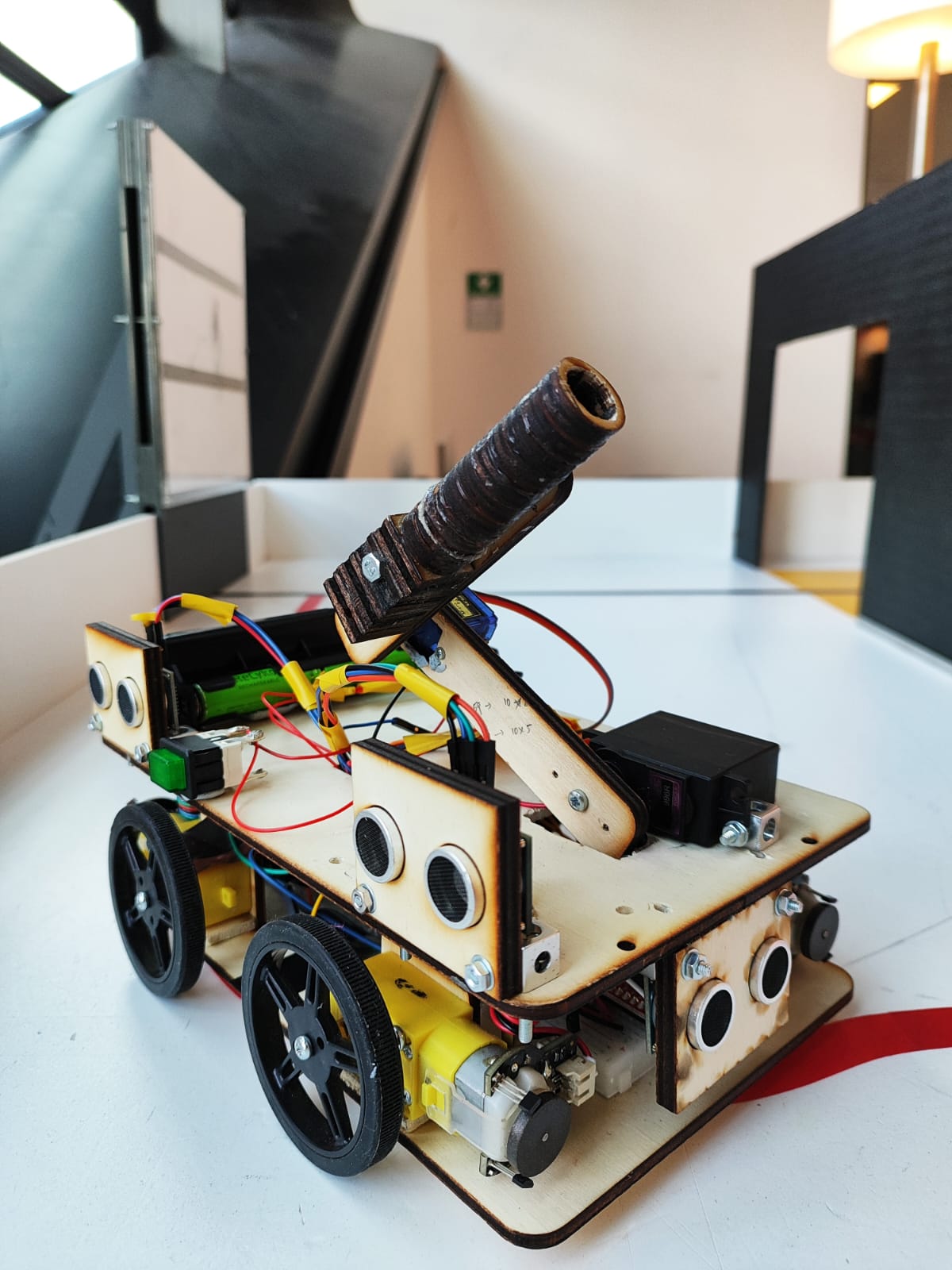

Designed and built a mechatronic robot featuring DC motors for mobility, servo motors for a marker-equipped robotic arm, and an Arduino Mega for control. The robot successfully demonstrated autonomous drawing and precise navigation through an arena, integrating inverse kinematics for smooth operation. The project showcased skills in CAD design, embedded systems, and collaborative engineering.

Smart Helmet is an Arduino-based safety system designed to ensure motorcyclists wear helmets and avoid drunken driving. It uses sensors (tactile switch, MQ135 alcohol sensor, and IR eye-blink detector) to prevent bike ignition if safety rules are violated, while an anti-sleep alarm alerts drowsy riders. The project highlights embedded systems' potential to reduce accidents and can be expanded with GPS/GSM for real-time tracking.